Safety mats HSM

Machines are frequently associated with hazard areas for your employees. Some operations of a machine within a certain radius can lead to serious injuries. Organisational measures such as labelling or marking have proved to be insufficient. It goes without saying that the immediate danger areas of machines and plants may only be accessed when the machine or system is switched off. Our safety mats are ideal for this type of protection.

What is a safety mat?

Safety mats are highly responsive safety devices which ensure that the machine power is stopped immediately if a person steps on a safety mat. Furthermore, the machine cannot be switched on again as long as the person is standing on a safety mat.

With our safety mats HSM for equipment such as machining centres, portal milling machines, presses, industrial robots and many other fields of application, we ensure that a machine or system is put into a safe operating mode as soon as a person enters the hazard area and for as long as a person remains in such an area.

Get advice from your regional contact now!

Functionality and structure

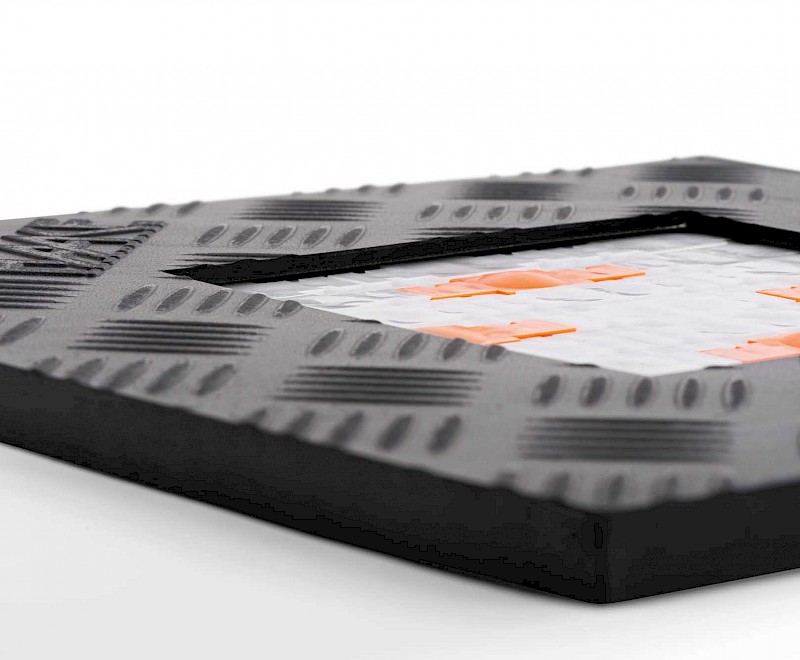

Our safety mats HSM consist of series-connected contacts based on positive opening operation principle arranged in the form of a contact mat - comparable to the unique Haake contact chain.

Electrically conductive contact plates and insulating wedge elements are placed alternately on an expander cord. With the help of pre-tension force, the contact elements are pressed together, and the closed circuit is completed. Upon stepping on a safety mat, the wedge-shaped elements disconnect at least one of the contact elements. This breaks the closed circuit - and the machine or system stops. Conversion of the output signal is therefore unnecessary, as a break contact signal is transmitted directly to the relevant emergency stop module of the secured machine.

The contact sensor contained within is embedded in a polyurethane material. The surface covering has an anti-slip design. Our safety mats are secured with aluminium fastening profiles, designed to suit your particular application.

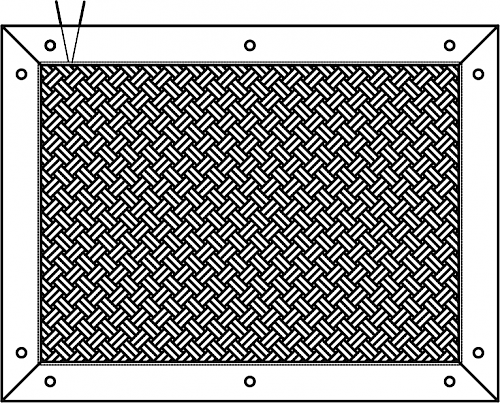

One contact sensor for many applications

No matter the shape, dimensions, materials or surface characteristics - configuration of a safety mat depends entirely on the individual requirements of your application. In addition to the standard rectangular shapes, custom shapes are available as well. A wide variety of materials and surface configurations are available depending on your individual application. Securing larger areas can be achieved by placing several safety mats next to each other.

Feel free to contact us, and we will be happy to develop a suitable solution together with you.

Overview of your benefits

- Highest safety standards: our safety mats meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Extremely robust: ideal for aggressive environments by using only high-quality materials.

- Individualisation: custom-made dimensions, a wide range of surface coverings depending on the application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our safety mats are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

- Plug and play based on customer specifications: ready-to-mount safety mats, including pre-finished frame profile. Safety mat is connected directly to the available emergency stop module of a machine or a system.