Preventing acccidents with Conveyor systems

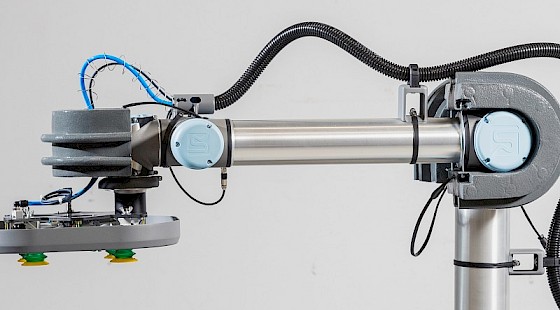

In assembly logistics, modern conveyor systems are used especially for flexible assembly concepts, such as component assembly in electromobility. Such conveyor systems must be safeguarded against collisions in order to protect people. The safeguarding of such applications is a particular challenge because these machines have a high moment of inertia and long stopping times.

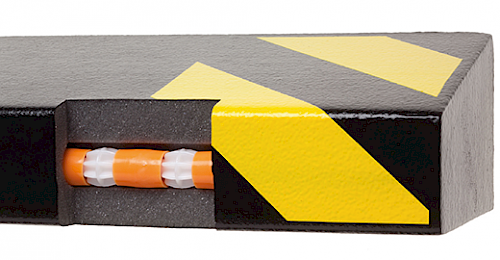

To safeguard such applications, we have been developing and supplying high-quality and reliable HSB safety bumpers , also known as switching buffers, for over three decades. These are contact-sensitive sensors that detect contact with a person or part of a person's body. If a bumper detects contact or an obstacle, the automatic drive of the machine is switched off immediately.

Development of an individual safety bumper - a case study

With our standardised cross-sections and materials, we secure a large number of applications in practice. For particularly challenging applications, we develop customised security solutions that are completely tailored to the individual requirements and wishes of our customers with regard to dimensions, shapes, colouring and the materials used.

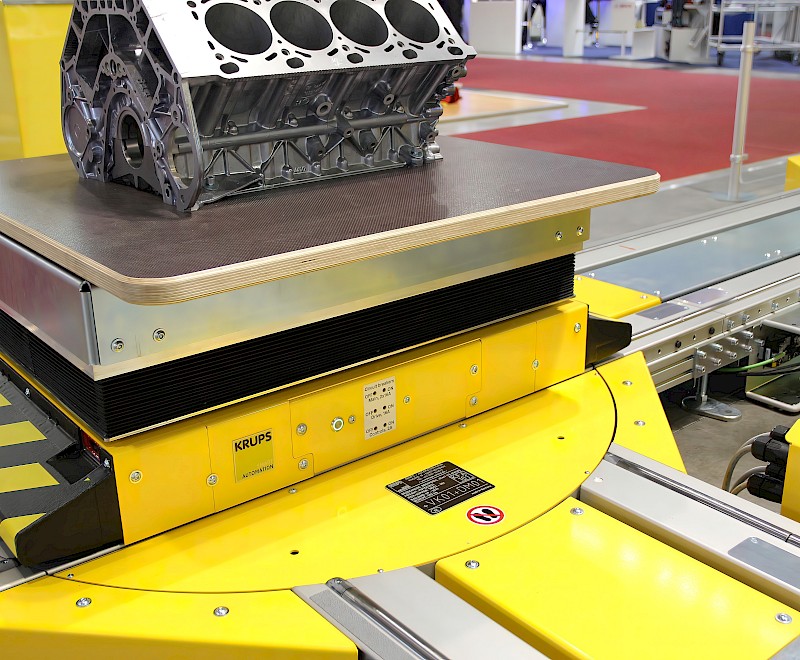

This was also the case when securing the LOGO!MAT eCart of our long-standing customer KRUPS Automation GmbH. You can see in this video how the development, production, delivery and installation of our HSB safety bumper on the LOGO!MAT eCart works.

Many thanks for the close and successful cooperation!

Pour activer la vidéo Youtube, vous devez accepter les cookies marketing.

Adapter l'approbationOverview of your benefits

- Highest safety standards: our bumpers meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Optimal switching performance: minimal force required to trigger the switch and short feedback signal paths Depending on the application, various contact chains are used to achieve an optimal switching behaviour.

- Customisation: a wide range of dimensions, shapes and colours are available depending on your specific application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our bumpers are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

- Plug and play based on customer specifications: safety edge is connected directly to the available emergency stop module of your machine or equipment.

Adobe PDF RFQ forms to fill in, download and send!

FAQ : Questions fréquentes sur la sécurisation des zones de cisaillement et de pincement

Les systèmes de convoyage modernes présentent souvent une forte inertie et de longs temps d’arrêt. Sans mesures de sécurité supplémentaires, une collision peut entraîner de graves blessures. Une sécurisation fiable est donc indispensable.

Les pare-chocs HSB sont des capteurs sensibles au toucher. Dès qu’ils détectent un contact avec une personne ou un obstacle, ils envoient un signal au système de commande et l’entraînement s’arrête immédiatement.

Ils sont utilisés notamment dans l’électromobilité, par exemple pour des concepts d’assemblage flexibles ou le montage de composants. Un exemple pratique est la sécurisation du LOGO!MAT eCart de KRUPS Automation GmbH avec des pare-chocs HSB personnalisés.

Oui, les systèmes sont modulaires et peuvent être intégrés dans des convoyeurs existants sans modifications majeures.