Development of an individual key transfer system for HAZEMAG - an application example for securing impact crushers

In some industrial sectors, machines and systems are used that are designed in such a way that they require a stopping travelling way until they come to a complete standstill. In other words, even if they are switched off, it takes time for them to come to a standstill. A grinder, for example, has such a run-on process and harbours the risk of a fatal catchment area if the standstill is not waited for.

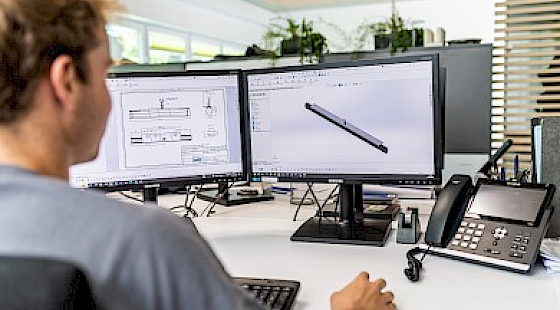

In order to rule out such dangers and thus accidents, HAZEMAG & EPR GmbH has opted for the longstanding, robust and proven sequential protection provided by a HAAKE HST® key transfer system.

To open the guard locking device on the Hazemag impact crusher and activate the release of the HAAKE HST® M key, the user must first switch off the machine. Only after the grinder has come to a complete standstill can a switch be pressed and the key released. This key can now be used to open the service flap in the HAAKE HST® tumbler device on the impact crusher - the key is trapped in the tumbler device.

As long as the service flap is open, the key cannot be removed. This is only possible when the flap is closed. This ensures that the machine cannot be started if a person is in the danger zone.

We would like to thank HAZEMAG for the continuously pleasant co-operation!

As a global partner in the cement, aggregates, recycling and mining industries, HAZEMAG offers sustainable success with a multitude of product innovations, application experience and technical excellence. More information about HAZEMAG can be found here:

Overview of your benefits

- Ease of use: Your employees can quickly and easily learn how to operatethe system regardless of their qualifications. This increases acceptanceand reduces motivation for manipulation.

- Individually coded keys and locks with a high number of codes: The operatingsequence is forcibly predetermined by the individual codedkeys and locks. The risk of accidents due to bypassing or incorrect operation is reduced to an absolute minimum.

- Individual and difficult-to-copy key design and controlled key issuance by HAAKE Technik: Within your facility or application, we prevent the existence of uncontrolled spare keys that would allow by passingof the safety function.

- Purely mechanical, without wiring: Our system can be easily and costeffectively installed, and the safety function is permanent, i. e. guaranteed even in the event of a power outage.

- Maintenance-free

- Simple retrofitting is possible: Already delivered systems can be easily expanded or supplemented afterwards.

- High mechanical robustness and resistance to harsh environmental conditions:You can confidently use our trapped-key interlocking system in environments where other protective devices quickly fail. Due to its very high robustness and durability, you also save costs for spare parts procurement.

Get advice now from your regional contact now!