Development of custom safety edges for ALTEK Hebetechnik GmbH

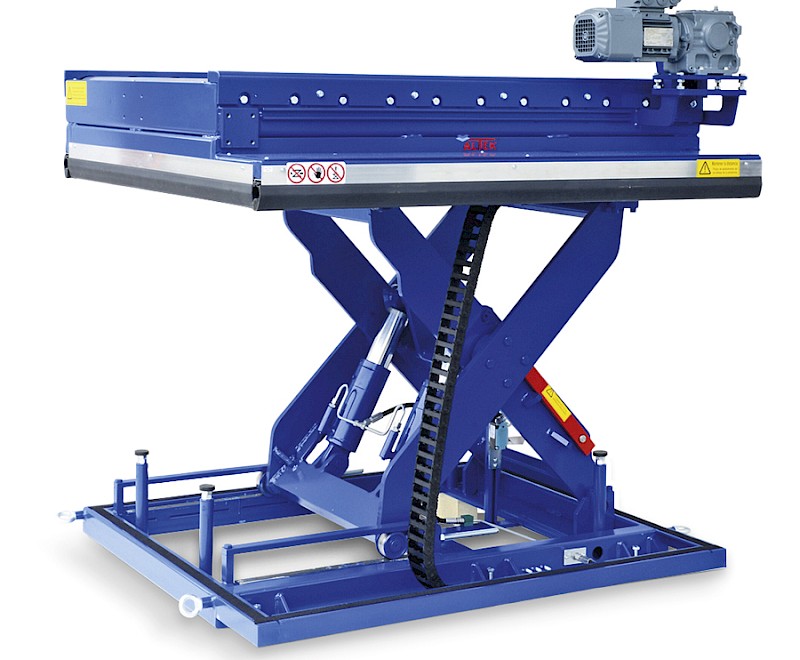

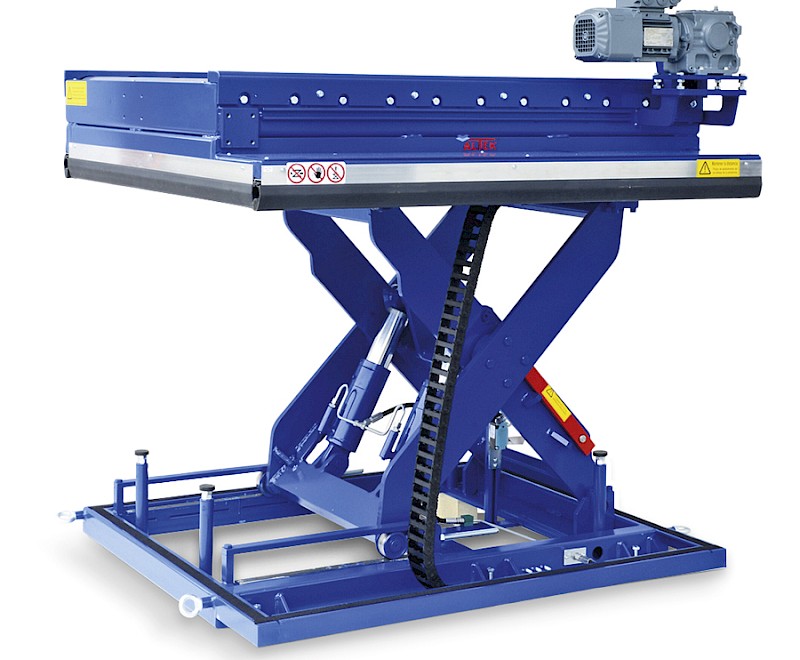

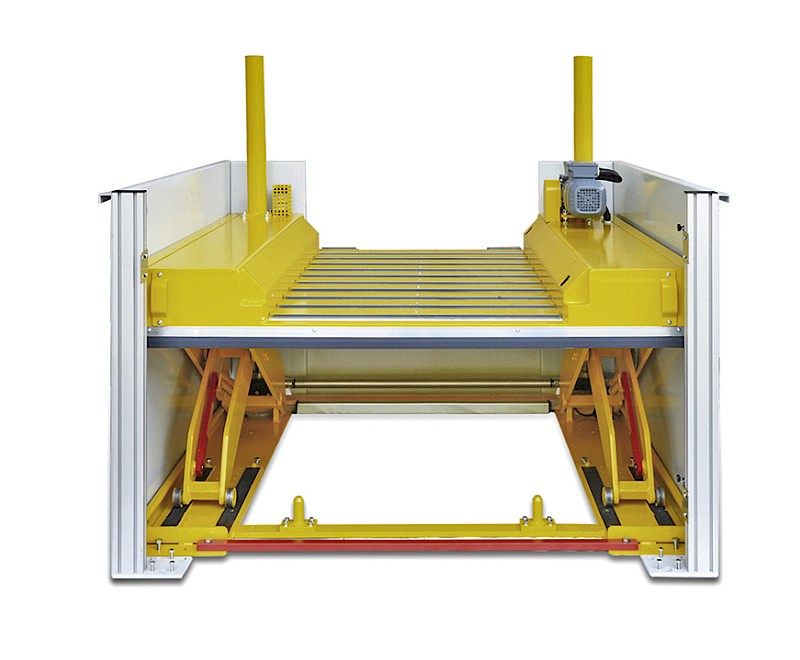

In industrial settings, modern lifting and conveying technologies are frequently employed. Many of these systems, such as lifting tables or elevators, are automated and electrically movable, posing potential risks to both peopleand materials. In the event of a collision, there is a risk of shearing and crushing injuries or, in pinch points, even more severe consequences, such as a trapped hand. To proctect employees it is essential to properly secure these

systems.

The high-quality and reliable HAAKE safety edges, known as HSC®, excel in precisely this role. They safeguard automated applications and thereby protect users from potential hazards. When the touch-sensitive sensors of the safety edge detect contact with a person, body part, or any other obstacle, the machine‘s drive is immediately halted.

ALTEK Hebetechnik GmbH develops innovative solutions and products in lifting technology for its customers. This includes state- state-of-the-art lifting tables as well as driverless transport systems and other special equipment.In addition to their standardized range of safety switching edges, HAAKE Technik provides a variety of safety edge variants designed and manufactured according to individual safety requirements and application scenarios. This also applies to ALTEK Hebetechnik GmbH. For many years, ALTEK Hebetechnik GmbH has depended on HAAKE safety edges to ensure the comprehensive safety of their systems and equipment by securing the shearing and pinching edges of their products.

Overview of your benefits

- Highest safety standards: our safety edges meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Optimal switching performance: minimal force required to trigger the switch and short signal feedback paths. Triggering of the contact chain signal independently from the direction of its activation.

- Customisation: wide range of safety edges to suit your individual safety requirements and application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our safety edges are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

- Plug and play based on customer specifications: safety edge is connected directly to the available emergency stop module of your machine or equipment.

Get advice now from your regional contact now!