Application example: Safeguarding of pressure safety valves (PSV)

Wherever piping is used for production processes, pressure safety valves (PSV) can be found. To prevent over pressurisation within the system during maintenance work, it must be ensured that a minimum number of PSV lines is always opened. The use of our valve interlocking systems HSV® ensures that a predefined, safe sequence of opening and closing of the corresponding valves is maintained. In the below example of a chemical production site both PSV lines are open during normal operation. The operator must close a line before maintenance work can be carried out. Our valve interlocking systems HSV® guarantee that the operator can only close one of the two lines at any time.

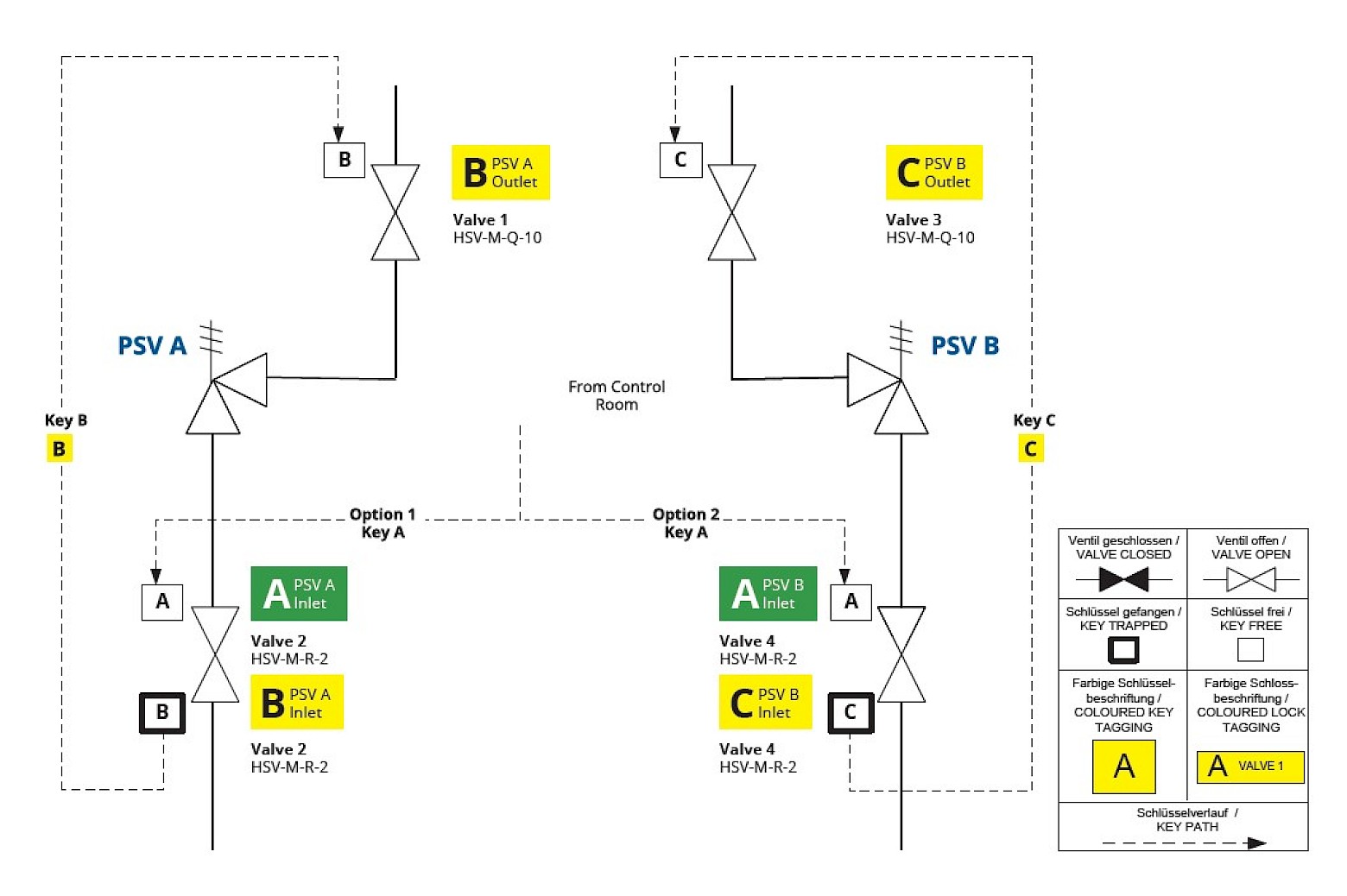

This realisation of the safety requirement is illustrated in our key logic diagram. With the start key A, which is safely stored in the control room, the authorised operator can decide which of the two lines should be closed. This key is designed in such a way that it can unlock both inlet valves of the two PSV lines. As the key is trapped after closing the selected valve, it ensures that the second line cannot be closed if the first line has already been closed. Only after the line to be services has been fully re-opened, key A is released and can be used to close the other line.

Take key A from Control Room

Insert key A into interlock of Valve 2 PSV A Inlet to unlock and close valve.

Lock Valve 2 PSV A Inlet in closed position by removing key B . Valve 2 is now locked closed with key A trapped.

Insert key B into interlock of Valve 1 PSV A Outlet to unlock and close valve.

Key B is trapped as long as valve is closed.

Repeat above sequence in reverse order to restore the normal operating condition.

Overview of your benefits

- Ease to use: Your employees can learn how to operate the system quickly and easily, regardless of their qualifications. This increases acceptance and reduces the motivation for manipulation.

- Individually coded keys and locks with a high coding number: The operating sequence is predefined by the individual keys and locks. The risk of accidents due to bypassing or incorrect operation is reduced to an absolute minimum.

- Individual and difficult-to-copy key design and a controlled key providing by Haake Technik: We prevent the existence of uncontrolled spare keys within your system or application, which would allow the security function to be bypassed.

- Ergonomic key that can be inserted from both sides with early detection: The simple and transparent operation ensures a fast and trouble-free work process, thus increasing operator acceptance. In addition, early key recognition prevents potential damage to the lock and consequently reduces repair and maintenance costs.

- Mechanical, without wiring: Our system is easy and inexpensive to install and the security function is permanently guaranteed, i.e. even in the event of a power failure.

- Maintenance-free

- Simple retrofitting is possible: Systems that have already been supplied can easily be expanded or supplemented.

- Continuous closing: In case of a leakage, it may be necessary to operate the valve in the locked and closed condition. With the help of our valve interlocks with continuous closing feature, a valve that is locked in the closed condition can be closed further without a key, in order to close a leakage without going through the entire operating sequence.

Get advice from your regional contact now!