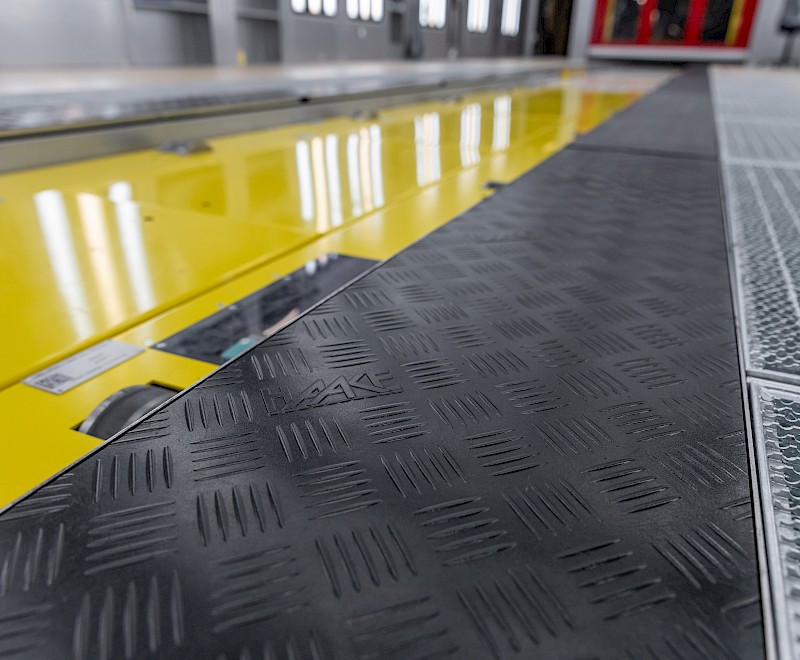

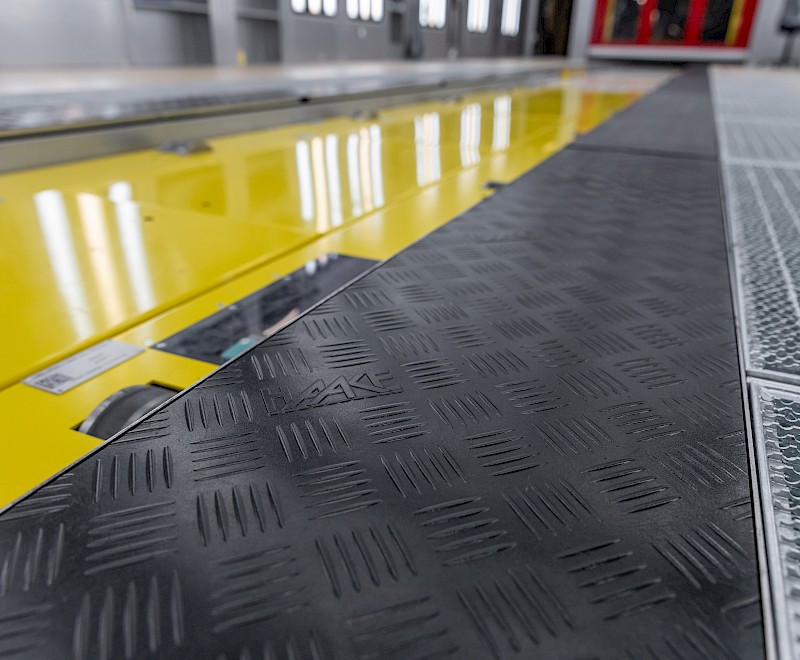

Development of customised safety mats for the BMW Group

In the automotive industry, modern automated production lines are utilized, where the swift flow of automobile bodies to be manufactured is of paramount importance. To protect individuals against potential collisions with the conveyor system or semi-finished products, these automated production lines need to be safeguarded.

HAAKE Technik offers a variety of different contact mats, the configuration of which can be tailored to the specific requirements of each application. You can also find a custom-designed concept for securing the area of a production line using HAAKE safety mats (HSM) at the BMW Group Leipzig plant.

Every production line has its unique safety requirements, including the production line for automobile manufacturing at the BMW Group. An individually tailored concept for securing potential hazard areas was created by customizing Haake switching mats (HSM) to meet the specific needs of this customer. The tactile area protection provided by HAAKE safety mats ensures that when employees step on them, the production line comes to a halt, preventing collisions with the conveyor system or vehicle body. Conversely, the production line cannot be restarted as long as an employee is on the safety mat.

This principle of touch-sensitive sensors was perceived as an advantage over optical safety systems, as it eliminates the possibility of false triggers, such as detecting particles in the air.

Overview of your benefits

- Highest safety standards: our safety mats meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Extremely robust: ideal for aggressive environments by using only high-quality materials.

- Individualisation: custom-made dimensions, a wide range of surface coverings depending on the application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our safety mats are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

- Plug and play based on customer specifications: ready-to-mount safety mats, including pre-finished frame profile. Safety mat is connected directly to the available emergency stop module of a machine or a system.

Get advice now from your regional contact now!

FAQ: Frequently Asked Questions about Area Safeguarding of Production Lines

In automated manufacturing processes, conveyors and semi-finished products move at high speed. Without suitable safety measures, there is a risk of collisions with employees. Area safeguarding reliably prevents such accidents.

The safety mats are tactile sensors. As soon as a person steps on the mat, the circuit is interrupted and the production line is stopped immediately. The system can only be restarted once no one is standing on the mat.

Optical systems can cause false triggers due to dust, particles, or light reflections. Tactile safety mats respond only to actual physical contact with a person, making them particularly reliable.

They are used wherever areas need to be reliably safeguarded – for example, in automated production lines in the automotive industry. One example is the BMW Group plant in Leipzig, where customized HSM safety mats were installed.

Yes, Haake Technik develops a tailored concept for each production line – from standard solutions to custom-made special designs, adapted to the specific requirements of the system.