Safety Bumpers HSB

Protection of shearing and crushing points for large and heavy power-operated facilities such as hangar doors, theatre stages or automated guided vehicle systems (AGVs) pose a particular challenge because they have a high moment of inertia and long stopping distances.

Our safety bumpers HSB which are able to absorb longer braking distances serve to protect against these kinds of hazards. They operate according to the highly effective and reliable normally closed contacts principle and ensure that the automatic actuation is stopped immediately upon contact, e.g. with part of a body.

What is a bumper?

Safety bumpers are contact-sensitive devices that detect contact with a person or part of a person's body. Should a bumper register a contact or an obstacle, the automatic drive of the machine is immediately stopped.

While safety edges are fitted with one sensor, bumpers can be equipped with several signal transmitters and also feature an actuating surface that is usually over 80 mm.

Safety bumpers are therefore particularly effective in protecting the shearing and crushing points of large and heavy powered equipment. Here is just a small selection of the machines and systems that use our safety bumpers HSB:

- Theatre stages

- Hangar doors

- Automated guided vehicle systems (AGVs)

- Lifting and work platforms

Overview of your benefits

- Highest safety standards: our bumpers meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Optimal switching performance: minimal force required to trigger the switch and short feedback signal paths Depending on the application, various contact chains are used to achieve an optimal switching behaviour.

- Customisation: a wide range of dimensions, shapes and colours are available depending on your specific application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our bumpers are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

- Plug and play based on customer specifications: safety edge is connected directly to the available emergency stop module of your machine or equipment.

To activate the YouTube video, you must agree to the marketing cookies.

Adjust consentFunctionality and structure

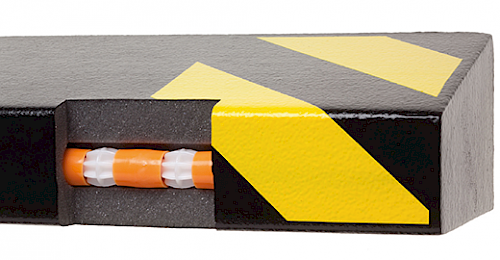

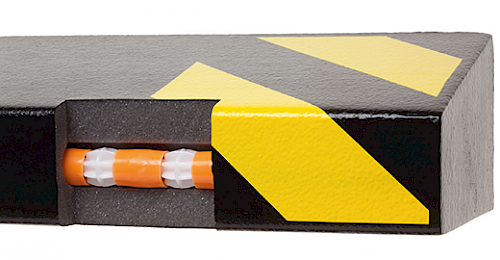

Our bumpers consist of a foam housing with the Haake contact chain installed inside. The foam housing is covered with a highly abrasion-resistant elastic polyurethane coating. There are additional materials and solutions available to suit applications involving harsh environmental conditions (e.g. aggressive media).

The Haake contact chain consists of electrically conductive contact rolls and intermediate insulating elements connected in series. These are arranged alternately along an expander cord. With the help of pre-tension force, the contact rolls are pressed together; and the closed circuit is completed.

When activated, at least one of the contact roll pairs is isolated with the wedge-shaped insulating spacers. This breaks the closed circuit. Conversion of the output signal is therefore unnecessary, as a break contact signal is transmitted directly to the relevant emergency stop module of the secured machine.

A pressure sensitive sensor, tailored to fit your individual safety requirements

With our standardised cross-sections and materials we are able to cover a large number of potential applications. For particularly challenging applications, we develop customised safety solutions that are tailored to your individual requirements and wishes in terms of dimensions, shapes, colouring and the materials used.

You can get an insight into the implementation of such special requests via this links under our heading case studies:

>> Protection of shearing and crushing points in assembly logistics

Get advice from your international contact now!

FAQ: Frequently asked questions about safety bumpers

Safety bumpers, also called switch buffers, are touch-sensitive sensors. As soon as they come into contact with a person or an obstacle, they immediately shut down the machine drive. With a larger activation surface than safety edges, they are particularly suitable for protecting large, heavy machines with long stopping distances.

Typical applications include theater stages, hangar doors, automated guided vehicles (AGVs), lifting and work platforms, as well as pinch and shear points in logistics or on robots. Wherever high mass and inertia pose risks, bumpers ensure reliable protection.

Inside is the Haake contact chain, consisting of conductive rollers and insulating elements. These keep the closed-circuit system intact until contact occurs. When the bumper is activated, at least one contact opens, the circuit is interrupted, and the drive stops immediately. No signal conversion is required, since an opener signal is generated directly.

They provide a high safety level according to DIN ISO EN 13849-1 and respond with low force and short travel. Thanks to durable materials and customization in size, shape, and color, they are highly versatile. They also save costs, as no special evaluation device is needed, and can be easily connected via plug & play to existing emergency stop modules.

Yes, alongside standard solutions Haake Technik develops tailored versions. Dimensions, materials, and colors can be adapted individually, ensuring safety even under special operating conditions.